CRG Research Report - © 1998-2021, Camaro Research Group

1967-1969 Camaro OEM Window Glass

Primary Author -

Reviewed by the CRG

Last Edit: 29-Jan-2021

Previous Edits: 15-Sep-2019, 30-Jun-2007, 27-Feb-2006, 30-Sep-2002,

17-Aug-2000, 19-Mar-2000, 24-Sep-1999, 13-Aug-1999

Original Release: 23-Dec-1998

|

Index

Overview

First-generation Camaro window glass was supplied by two manufacturers: Libbey Owens Ford

(LOF) and Pittsburgh Plate Glass (PPG). LOF was the overwhelming supplier for '67-'68 models,

and the dominant supplier in '69. PPG acted as an alternative supplier of Camaro glass and

was the primary supplier in '67-'69 to the sister model of the Camaro, the Pontiac Firebird.

Either supplier for could provide glass to either GM division in the event of a shortage,

but the only PPG glass use that CRG has verified to date in 1967-68 Camaro is the

occasional use in 1967 vent window glass. There was an increase in the amount

of PPG glass in '69 Camaros, especially at the Norwood Camaro assembly plant,

possibly due to the production of the Firebird moving to Norwood in April of 1969.

(LOF was purchased by Pilkington, which was then purchased by Japanese supplier NSG (Nippon

Sheet Glass), which then abandoned the LOF trade name in order to consolidate global

operations. While LOF glass for classic restorations had been reissued for a time under

Pilkington management, that classic glass division was shut down after the NSG acquisition

and those products with vintage markings are no longer available from NSG/Pilkington.)

During the late 1960's, LOF had a number of automotive glass manufacturing facilities.

The primary LOF manufacturing sites for Camaro glass were LOF Plants 6, 8, and 10. Plant 6,

in Rossford, OH (next to Toledo), supplied tempered glass to both assembly plants (to-date,

CRG has found only vent window glass from this factory in Camaros). LOF Plant 8 primarily

supplied Norwood. Plant 10 in Lathrope, CA primarily supplied glass to the Van Nuys assembly

plant.

Despite the typical use of LOF Plant 8 glass at the Norwood Camaro factory, and LOF Plant 10

glass by the Van Nuys Camaro assembly plant, the evidence from original vehicle research

shows that each assembly plant infrequently used glass from the other LOF plant. This

was done sufficiently often that glass plant location cannot be used

as a primary discriminator for determining glass originality. (However

it can be useful "circumstantial" evidence, as a secondary

discriminator when combined with production dates, etc.)

While certain aspects of the marking systems of these two suppliers

were known, there were many glass details that were not known. We were fortunate

to be able to access the expertise of supplier experts for this information.

However, certain details had been "lost" due to the passage of time

and could only be determined by reviewing and documenting a large population of original

window glass.

Automobile Glass Manufacturing Processes

There were three different manufacturing processes used for auto glass

during the first-generation Camaro era:

- Plate Glass

- In the late '60's, it was still in common use, but as a

discontinuous process (the glass is made in discrete pieces)

manufactured by an older technology, it was gradually being phased out

in favor of float glass.

- Float Glass

- The successor to plate glass, float glass is created in a

continuous process of floating molten glass on molten metal, typically tin,

that results in higher uniform glass thickness and flatness at a lower cost.

Float glass is the predominate type in use currently.

- Laminated Glass

- The third glass type, used for windshields, is

laminated glass, which is fabricated by sandwiching and

bonding annealed glass (annealed glass has been processed to

reduce residual stress - unlike tempered glass)

on both sides of a tough transparent plastic

core. (Plastic by itself is too soft to be sufficiently

resistant to long-term abrasive wear of windshield wipers,

or even car washing.) In the late '60s, laminated glass had already long

been in use for windshields for safety purposes, as, upon severe impact,

the plastic core of laminated glass retains most of the glass fragments

and prevents many previously common occupant injuries caused

by foreign object impact to the windshield.

- Tempered Glass

- Tempered glass results not from a glass creation process, as does

plate and float glass, but from a post-processing thermal treatment.

In automotive use, both plate glass and float glass are tempered to

improve damage tolerance. Glass, by itself, is not damage resistant;

it is easily scratched by a hard object, and since glass has a very

low fracture toughness, small surface scratches result in failure /

breakage at very low tensile stress levels.

However, plate or float glass can be made more damage tolerant by

inducing a compressive stress on the surfaces of the glass by means of

a thermal treatment. If the surfaces of the glass are placed in a

pre-loaded compressive stress state via the tempering process, the

inevitable minor surface scratches (cracks) do not experience a

tensile stress, and thus cannot easily grow under typical loads. This

results in a much more durable, and safe, glass product.

Both tempered float glass and laminated glass remain in common automotive use

today. Plate glass is no longer produced for automotive use in the US.

Government Regulatory Safety Standards

By the mid-1960's, specific safety standards for glass had been

enacted into law by individual states as well as by the U.S. Federal

government, affecting glass development and usage. However development

and passage of the landmark Motor Vehicle Safety Act of 1966 was a

prime motivator for many changes during this period. This U.S.

legislation also created NHTSA, the National Highway Traffic Safety Administration,

a division of the U.S. Department of Transportation (DOT).

NHTSA develops federal standards on automobile safety, three of

which are recorded in Volume 49 of the Federal Motor Vehicle Safety

Standards (FMVSS); Code of Federal Regulations, 571.205. They are

standard numbers 205, Glazing Materials (glass); 209, Seat Belt

Assemblies; and 108 on Lamps, Reflective Devices and Associated Equipment.

FMVSS Part 205 on glass, which originally took effect on 1 Jan 1968,

initially referenced SAE J673 (Jun 1960), an earlier performance

specification for motor vehicle glass developed by the Society of Automotive Engineers (SAE).

The reference was later changed to ANSI Z26, an update of J673 that is

maintained by SAE but published by the American National Standards Institute

(ANSI). This performance specification is the one that all

manufacturers of vehicles being sold in the U.S. are required to meet.

The vehicle manufacturers, in turn, flow this requirement down to the

glass manufacturers.

Glass terms previously in use but obsoleted with the advent of Federal

glass standards, include:

- single-strength

- 0.090-inch (3/32-inch) thick glass.

- double-strength

- 0.125-inch (1/8-inch) thick glass.

Glass Marks

Federal Marks

The new Federal regulations at the time of the first-generation

Camaro required only four types of marks on motor vehicle glass:

- the AS (American Standard) number (classified by ANSI Z26

and Part 205),

- the M (Model) number (assigned by the manufacturer),

- for shaded glass, the start of the AS-1 portion that meets the

clarity requirement must be so marked on the windshield (located

on the passenger side, and shown in the illustration below from the exterior), and

- (eventually, for later glass) the DOT manufacturer number (assigned by NHTSA)

| AS-1 Mark on Shaded Windshield |

|

1967 Van Nuys Backlight

Plate Glass, M55 AA |

| |

|

State Marks

Historic state regulations, many not yet revoked, required other

additional marks, such as "Safety," "Solid Tempered," and "Laminated,"

as appropriate.

GM Marks

Additionally, General Motors itself required several specific marks on

OEM glass, including:

- Shaded

- Added to tinted GM OEM windshields when they

included the upper, dark (non-AS1), tint band. For

regulatory purposes these windshields are only AS1 glass

below the tint band.

- Plate

- Added to plate glass for GM OEM applications.

- Flo-Lite

- Added to float glass for GM OEM applications; Flo-lite is

a GM tradename and is not used for other OEM glass.

- Soft-Ray

- Added to tinted GM OEM glass. Soft-Ray is a GM tradename and

is not used for other OEM tinted glass. Tinted OEM glass of

this era was green in color, whereas current Soft-Ray glass is blue.

For LOF and PPG to produce glass with GM specific marks with minimum

risk and maximum manufacturing freedom, agreements between the

suppliers and GM allowed for excess OEM glass that was not purchased

by GM to be sold by LOF or PPG on the aftermarket, while retaining

the GM tradenames of Soft-Ray and Flo-Lite.

Supplier and non-GM OEM Tradenames

Glass supplier tradenames, like "Duplate," "Solex," "E-Z-Eye," and

"SunShade" do not appear on GM OEM Camaro glass. Glass tradenames from other

OEMs also obviously did not appear on GM glass. For example,

"Safeguard," which is a tradename for Chrysler glass.

The "AS" Glass Classifications

The AS (or American Standard) glass codes are listed in the ANSI Z26

standard classification of motor vehicle glass produced by the Society

of Automotive Engineers (SAE). Note that ANSI Z26 is a "performance"

standard that sets minimum requirements for the functional performance

of a product. In other words, it doesn't tell manufacturers how to make the glass

but rather what functions the glass must perform. While a number of

motor vehicle glasses are listed in this standard, for

first-generation Camaros there are only two classifications that apply:

- AS-1 Laminated glass, windshield only

- Must pass the various ANSI Z26 tests/requirements for windshields,

which include impact standards and a minimum of 70% light transmissibility.

AS-1 glass is typically composed of two pieces of 1/8-inch glass

laminated on either side of 0.030-inch of PVB plastic.

- AS-2 Laminated or tempered glass, side/rear only

- This glass is required to pass ANSI Z26 tests for side glass,

including side impact requirement and a minimum of 70% light

transmissibility. This glass is typically composed of one sheet of

thick tempered glass (Solid Tempered) or (not seen on Camaros) two

layers of thinner glass laminated to either side of a 0.015-inch PVB

plastic core.

LOF Glass Markings

Marks from 1966 through December 1968

Transcriptions of two different examples of the variations of LOF

OEM glass markings are seen below in their pre-1969 version

(e.g., without the DOT mark). Note that "date/plant" is not

literal but indicates the location of the Date and Glass Plant code

discussed later. See also the later discussion of marking details,

such as hyphen use.

SOFT-RAY

SAFETY L PLATE SAFETY L FLO-LITE

AS2 O date/plant AS-2 O date/plant

F F

SOLID TEMPERED SOLID TEMPERED

M51 M74

DOT code added in calendar year 1969

While not part of the original regulations under Part 205, subsequent

revisions required addition of a manufacturers "DOT-xx" code to the

glass label. DOT numbers for auto glazing were required to be

effective April 1, 1973.

The LOF number is 15, and the PPG number is 18. While not required by law,

LOF began marking their glass with the DOT

number as soon as it was assigned and the glass stencils were updated.

This DOT mark is first noticed beginning with January 1969 LOF glass

production. We believe that glass on Camaros built prior to January 1969 should

not show the DOT mark. An example transcription of DOT marked glass is shown below.

SHADED

SOFT-RAY

SAFETY L FLO-LITE

AS1 O date

F

SOLID TEMPERED

DOT 15 M4

LOF Glass Model Numbers

As described previously, vehicle glass was manufactured by three

different processes; Plate, Float (Flo-Lite), and Laminated; in both

clear and tinted types, and in two different thickness (for Plate and

Float). There were 10 different types of glass in common use. LOF

assigned model numbers to each type of auto glass, and each type

received a different model number mark as required by ANSI Z26. These

model numbers are discussed below and summarized in the application

table.

Three types of AS-1 glass were used for the windshield; M3 for untinted, M4 for tinted,

and M24 for 68-69 tinted glass made at plant 10 in CA. (It is not known why plant 10

used this M24 model number or if was different than the M4 glass). Eight types of AS-2 glass

were used in the rest of the car. The stronger, 1/4-inch thick, AS-2 tempered glass was

normally used in Camaro doors, since the door glass is large and

frameless with little support from the car when in the raised position

- and is especially vulnerable when the door is being slammed closed.

Thinner, 3/16-inch thick, AS-2 tempered glass was normally used in the

vent (1967), rear quarter, and backlight (rear window) positions.

These normative practices were

sometimes violated. In rare cases the thicker AS-2 glass was

substituted in areas where the thinner glass was normally used -

perhaps to keep production moving at the glass factory. There are even

a few rare cases observed, and then (to-date) only in 1967 model LOS

cars, where the thinner 3/16-inch thick glass was used in the doors.

1967-1969 Camaro LOF Glass Models

Model Rating Tint Thk Type Typical Application

------ ------ ---- ---- --------------- -----------------------

M3 AS1 No 1/4 Laminated Plate windshield

M4 AS1 Yes 1/4 Laminated Plate windshield

M24 AS1 Yes 1/4 Laminated Plate windshield (plant 10)

M51 AS2 No 1/4 Tempered Plate door

M52 AS2 No 3/16 Tempered Plate vent, quarter, backlight

M54 AS2 Yes 1/4 Tempered Plate door

M55 AS2 Yes 3/16 Tempered Plate vent, quarter, backlight

M71 AS2 No 1/4 Tempered Float door

M72 AS2 No 3/16 Tempered Float vent, quarter and backlight

M74 AS2 Yes 1/4 Tempered Float door

M75 AS2 Yes 3/16 Tempered Float vent, quarter and backlight

|

Marking Method

LOF sand-blasted almost all glass marks with a stencil. The

only exception was the early '68 model "Astro-Ventilation" mark, which used

fired-on white ceramic paint [a thank you for this correction goes to Dan

DelGratta of LOF]. Decals are incorrect. Also incorrect is reproduction

glass that uses baked on black enamel for marking (often seen on modern

glass, and still prevalent for the AS1 mark even on repo glass

that has had "correct" marks added). Note that there are some stencil

differences from one plant to another. LOF Plant 16, in particular, used a

distinctly different stencil from the other LOF plants that supplied

Camaro glass. Consistent marking patterns include:

1967-1969 Camaro LOF Glass Marking Patterns

Windshield - marked on outside for viewing from inside

Side glass - marked on EITHER side for viewing from inside

Backlight - marked on outside for viewing from outside

Astro-Ventilation - marked on inside for viewing from outside

logo (early 68)

|

LOF Date and Plant Codes

The LOF date code is a two-letter code - a one-letter month code followed by

a one-letter year code. For example, a code of NX is interpreted as January 1968.

LOF Plant Codes

Plant 2 Shreveport LA

Plant 3 Parkersburg, WV

Plant 4 East Toledo, OH

Plant 6 Rossford, OH

Plant 8 East Toledo, OH

Plant 10 Lathrop CA

Plant 11 Rossford OH

|

| |

1966-1970 LOF Glass Dating System

LOF Month Code - First Character

N X L G J I U T A Y C V

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

LOF Year Code - Second Character

A Z X V T N Y U L I C G J

1953 1954 1955 1956 1957 1958 1959 1960 1961 1962 1963 1964 1965

1966 1967 1968 1969 1970 1971 1972 1973 1974 1975 1976 1977 1978

1979 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991

|

|

The "-xx" suffix on the LOF date code is the plant code. "-10"

indicates the source was the Plant 10 Lathrope, CA facility that

supplied primarily the Van Nuys, CA Camaro assembly line. A "blank"

code (no plant code) was used by Plant 8 that supplied all windshields

to both Camaro factories, as well as tempered glass primarily to the

Norwood, OH assembly line. A "-16" code actually denotes Plant 6

rather than Plant 16 (which didn't exist); this plant supplied mostly

vent windows. For unknown reasons, there was an extra 1 prefix in the mask.

Our findings to date show the following marking variations:

- M3, M4, and M5x models did not use a hyphen in the ASx codes

while M7x models did use a hyphen in the AS-x codes

- M5x models used a narrower font for "SOLID TEMPERED"

than did the M7x models

The Astro-Ventilation logo was dropped from the 1968 door glass about

Nov or Dec '67 production. However, one pane of

apparently original May '68 door glass with the Astro-Ventilation logo

has been observed in a 05C build. The mating glass on the opposite

side of the vehicle is Sep '67 Astro-Ventilation glass. We believe that the May '68

pane had the Astro-Ventilation logo added by LOF to create a matching

set, presumably to use up left-overpanes. At least two other late '68 cars have

been observed with late 1967 Astro-Vent glass.

The DOT mark was added to most LOF glass during stencil changes made

for January 1969 production. However, this addition was not yet a

Federal requirement, and a few panes of non-DOT LOF glass have been

observed in 1969, but these appear to be the exception rather than the

rule.

PPG Glass Markings

The PPG Glass was marked with a combination plant and date code. The format

is PP-MMY, where PP is the plant code and MMY is the Month and

Year. So 27-29 was made in the Tipton, PA plant in February 1969, 27-109 was

made in October 1969. The plant codes and glass model information are:

PPG Plant Codes

Plant Location Focus

1 Creighton, PA OEM windshields

25 Greensburg, PA (non F-body)

26 Crestline, OH OEM rear/side glass

27 Tipton, PA OEM rear/side glass

28 Evansville, IN (non F-body)

41 Berea, KY (non F-body)

81 Oshawa, Ontario (non F-body)

|

| |

OEM PPG Glass Types

M20.x = untinted side/rear glass

M25 = laminated windshield glass

M27.x = tinted side/rear glass

The .x suffix indicates nominal thickness in 1/32"

.6 = 3/16-inch thickness

.8 = 1/4-inch thickness

The decimal point may be a space, or may be absent,

such as: M20.8, M20 8, or M208

|

|

Examples of PPG glass marks:

SAFETY Flo-Lite

Ex #1 AS-2 PPG 26 108

SOLID TEMPERED

M208

The SAFETY mark, AS code, GM Flo-Lite tradename, and SOLID TEMPERED mark are as described above.

"26" is the PPG plant code for Crestline, OH and "108" is the PPG date code, 108=Oct 1968.

The M-code is the PPG glass type for untinted side/rear glass at 8/32-inch thick

(1/4 inch). Note no decimal point or space prior to the thickness code in this example.

SOFT RAY

SAFETY PPG FLO-LITE

Ex #2 AS-2 27-97

SOLID TEMPERED

M27 6

In this second example of OEM glass, the GM tradename for their tinted glass, SOFT RAY

is the same as used on LOF glass. The plant/date code indicates Tipton,

PA glass made in September of 1967. The glass is type M27 (tinted M20) at

6/32-inch thick (3/16 inch).

SUNSHADE

PPG SOLEX

Ex #3 DUPLATE

Replacement LAMINATED

SAFETY PLATE

AS1 M30 25 102

DOT 18

Third example is of NON-OEM PPG windshield replacement glass. Sunshade and

Solex are PPG tradenames. Duplate was a PPG name for early laminated glass.

The type for this non-OEM glass is M30, the date is Oct 1972, and the DOT code

now appears.

Acknowledgments

The author particularly wants to acknowledge the help and assistance

of Mr. Sig Herliczek of Pilkington LOF and Mr. Frank Lovett of PPG, as

well as the helpful critique of the other members of the Camaro

Research Group. Many thanks are also owed the large number of Camaro

owners who patiently contributed original window glass data to this

project, oftentimes enduring repeated contacts for additional

information.

Appendix A

Glass Mark Photos

Ordered from the front of the vehicle to the rear.

1967

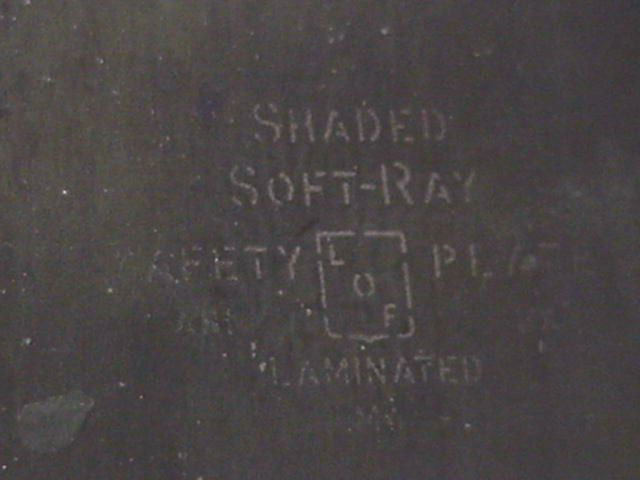

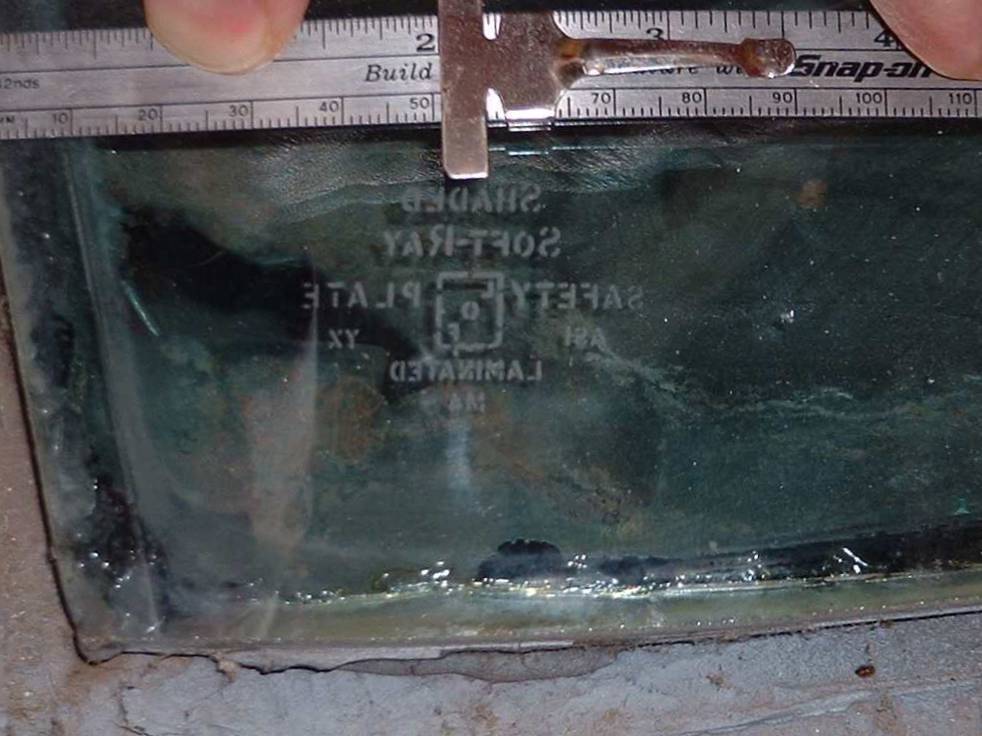

1967 Van Nuys Tinted Windshield

Laminated Glass, M4 VZ |

1969

1969 Norwood Tinted Windshield

Laminated Glass, M4 YX |

|

|

| |

1967 Norwood Psg Vent

Plant 16 Plate Glass, M52 XZ |

1967 Van Nuys Psg Vent

Plant 16 Plate Glass, M52 IA |

|

|

| |

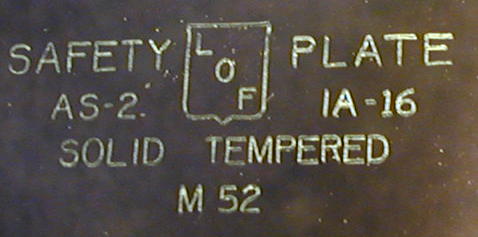

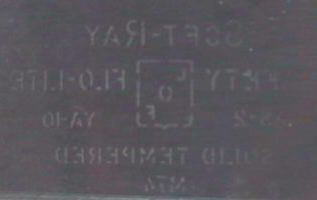

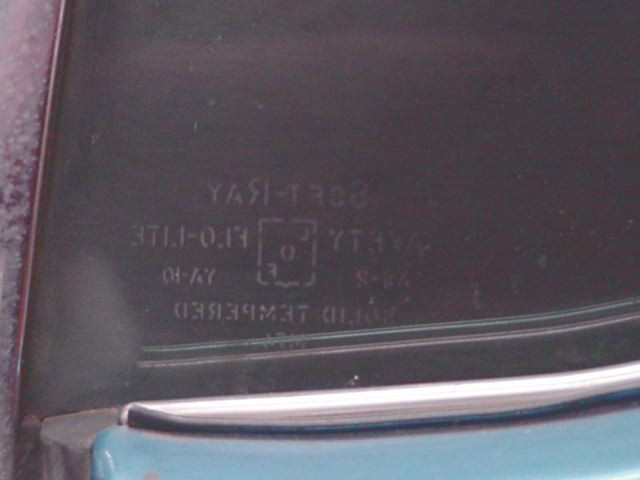

1967 Van Nuys Driver Door

Plant 10 Float Glass, M74 YA |

1969 (Plant unknown) Driver Door

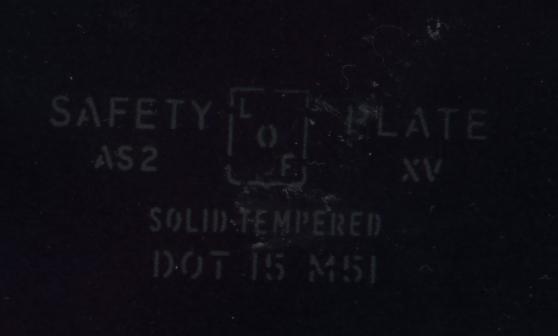

Plate Glass, M51 XV |

|

|

|

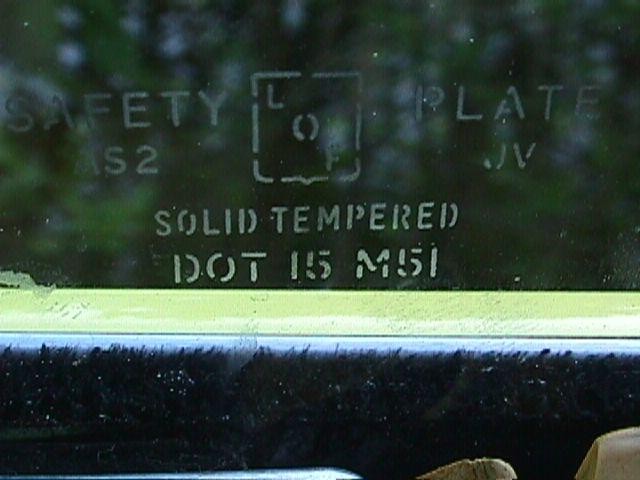

1969 Norwood Passenger Door

Plate Glass, M51 JV |

|

|

| |

1967 Norwood Driver Quarter

Plate Glass, M55 CA |

1969 Norwood Driver Quarter

Plate Glass, M52 JV |

|

|

| |

1967 Van Nuys Passenger Quarter

Plant 10 Float Glass, M74 YA |

1969 Norwood Passenger Quarter

Plate Glass, M52 JV |

|

|

| |

1967 Van Nuys Backlight

Plate Glass, M55 AA |

1969 Norwood Backlight

Plate Glass, M52 JV |

|

|