| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

CRG Research Report - © 2010-2025, Camaro Research Group

Camaro Foreign Assembly Plants

Author -|

Reviewed by the CRG Last Edit: 10-Nov-2025 Previous Edits: 22-Sep-2010, 10-Nov-2010, 24-Aug-2013, 26-Nov-2013, 26-Jan-2017, 26-May-2021 Original Release: 11-Mar-2010 |

|

Camaros were assembled at these five overseas factories: the Yutivo factory in Manila, Philippines (the subject of a CRG research article); GM Continental in Antwerp, Belgium; GM Suisse in Bienne, Switzerland; GM de Venezolana in Caracas, Venezuela; and GM del Peru in Lima, Peru. GM had other plants in various markets throughout the world that also built U.S.-designed vehicles, including Australia and Argentina, but they didn't build Camaros. All of these non-U.S. plants and the export activities were managed by GMOO (GM Overseas Operations) and GMODC (GM Overseas Distribution Corporation). We would be interested in talking to anyone who worked for either of these GM groups or who owns a foreign assembled or homologated car. Please contact us via email or via a post on the CRG forum.

The published Camaro production totals differ from the production totals from the Norwood and Los Angeles plants. The variance is 1200 units in 1967 and 1248 units in 1968. The 1969 totals match. It is not known if the unaccounted cars in the production totals were from the production of the foreign plants, but the numbers appear to be close to the approximate production of the foreign plants in 67 and 68. (It's obvious that for at least 69, that is not true since since known foreign production added to known domestic production totals is more than the published 1969 production total of 243,085 units.)

CKD bodies were assembled by the foreign plant from the individual sheetmetal stampings. The major body subassemblies (floorpan, LH/RH side panels, front and rear ends) were welded together. Those subassemblies were then joined together in a master jig to make the body tub. The body was painted and trimmed and then mated with the subframe / chassis assembly. Engines, transmissions, and axles were shipped as complete assemblies. Tires, glass, batteries, and some interior parts were often locally sourced. A more complete description of the CKD assembly process can be found in the Yutivo report.

|

Some CKD cars were exported to nearby contries - for example, Antwerp sent cars to Germany. But most countries without a CKD plant imported most/all of their Camaros from the U.S. GM International in Copenhagen imported cars into Denmark. Despite having a CKD plant in a neighboring country, both Chile and France imported cars from the U.S. Over 200 cars were imported into Sweden whereas only a few were imported into Japan. GM Limited imported cars for the U.K. market, though it's not known if they were only from the US or also from Antwerp. There were no 67-69 Camaros exported by GM to Australia (due to the right-hand drive requirements), but a few were imported and converted by private companies.

An export Camaro can often be identified via the trim tag.

- Many (1835 of the 4991) 1967's that were exported will have a 5O stamped

in the option field on the bottom of

the trim tag, denoting seatbelt delete. Seatbelts that met local requirements

were installed when the cars were homologated.

- 1968 export cars used the earlier 'Magic Mirror' style trim tag without the

Certificate of Compliance statement (see the

1968 Caracas tag below).

- 1969 export cars used a standard 1969 trim tag, but again without the

Certificate of Compliance statement stamped on the bottom of the tag (see the

1969 Caracas tag below)

A total of 4991 Camaros were exported to countries other than Canada in 67. Unfortunately, there are no export totals for 68 or 69, but the totals for the special cowl tags without the Certificate of Compliance statement are known. There were 1,445 built in 1968 and 1,466 built in 1969. It is not known if these tags were required for all export cars.

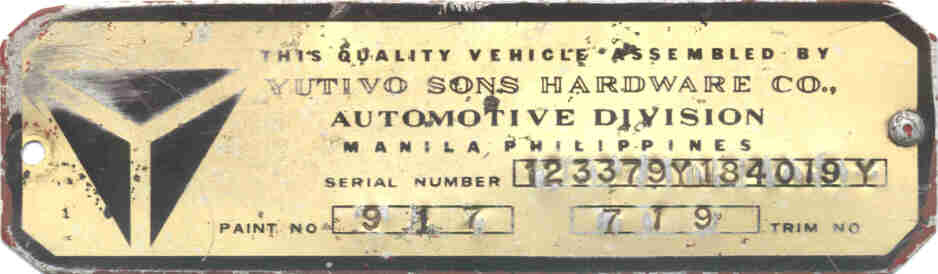

Yutivo used a ID tag attached to the passenger-side cowl that contained the VIN and the interior and exterior colors. The VIN format was a modified U.S.-format VIN with 14 digits instead of the normal 13 digits. Looking at the example below, "12337" is the style code for a Chevrolet Camaro 6-cylinder coupe. The "9" that follows represents the model year, 1969. The plant code was "Y" for Yutivo (note that Y was also used by GM for the Wilmington, DE assembly plant). The next 6 numbers "184019" were the Export Car Order (XCO) number followed by a letter. The XCO numbers started at 150000 in 67, 120000 in 68, and 184000 in 69. The letters A-Z (excluding I and O) indicated the unit number in the XCO. So there would be a 123379N184019A and a 123379N184019B, etc. Note that the other carlines that Yutivo made also used XCO numbers (i.e. XCO 184018 probably is a non-Camaro XCO).

The paint code format varied from year to year. The 67 codes were 5-6 digits, but their meaning is unknown. The 68 paint codes appear to be a DuPont paint formula, but they have not been cross-referenceable to a paint color. The 69 paint codes were three digits. Some codes may match the U.S window sticker RPO color codes, e.g. 917, but the meaning of other codes, e.g. 906, is unknown.

The interior trim codes were the same as the U.S. interior codes except that in 67, it did not include the suffix for the headrest / seat type.

|

Production in Antwerp has a long history, going back to 1925 when it assembled Chevrolets primarily for the Belgian, the Netherlands, and German markets under the name General Motors Continental. The factory was destroyed in WWII and new facilities were constructed in 1953 and expanded in 1967. The plant assembled 1967 and 1968 Camaros from CKD kits (along with Impalas, Firebirds, etc). Total CKD Chevrolet production in 67 was 1497 and 1139 in 68. Unfortunately the production quantities are not broken down by model, so the number of Camaros in that total are unknown. At the end of the 1968 model year, Chevrolet production ceased at Antwerp and the 69's were imported.

|

The engine options on the Antwerp-built cars included either the L26/140 hp L6 engine or a 327 engine - the 67 cars used the LF7 327/210 hp engine and the 68 cars used the L30 327/275 hp engine. Transmissions were either a Powerglide automatic or a 4-speed manual transmission. Cars were well-optioned and often included power disc brakes, power steering, console, gauges, rear defroster, fold-down rear seat, and deluxe interior.

| |

|

Sunroofs were a unique feature available on the Antwerp Camaros. The sunroofs were made by a German supplier and were optionally installed on both Antwerp-assembled vehicles and imported vehicles. When the sunroof was added to imported SUP's, a vinyl top was also installed (to hide distortions in the roof panel).

VIN's for the Antwerp cars were based on the U.S. VIN format with three notable differences.Examples of typical Antwerp VIN's would be 12537GX100123 or 12437HX101121.

The General Motors Continental Antwerp tag was mounted on the passenger-side

of the cowl. The 1967 tag was stamped with the following information:

Line 1: Make and model.

Line 2: Engine No., which was the

engine code and an 4-digit engine number (not related to the VIN) that the

plant generated and also stamped on the engine pad,

and the model number (e.g. 12537, which used the

original Camaro series designation).

Line 3: Chassis No., aka the VIN.

Line 4: Release number and the exterior color code. The Release

number was an internal tracking number for the unit that referenced the XCO number.

The format was year - XCO number - unit number.

The paint code generally used

Opel paint color codes.

Line 5 was the interior trim code, which was the same as the U.S.

interior codes except that it did

not include the suffix for the headrest / seat type. The weight fields (GVW) and

the Belgian certificate of conformity number (PVA) were not filled in.

|

The tag was changed for late 1967 cars and all 1968 cars. The tag now had recessed fields where the information was typed. The fields are now bilingual with two names or abbreviations on them - first is the Flemish and then the French. The same information was on the tag (though in different locations) with the notable exception of the removal of the Engine No. field and the addition of the maximum weight and maximum towing weight fields (which are often not completed).

|

|

Cars that were assembled by the Bienne plant received a unique emblem on the grille representing the Eiger, Monch and Jungfrau peaks and bearing the words "General Motors Montage Suisse" - Montage Suisse meaning "Made In Switzerland". Emblems on homologated cars had "General Motors Suisse SA Bienne" on them, since the cars weren't made in Switzerland.

Total Chevrolet production was 511 in 1967 and 343 in 1968, mostly for the Swiss market. Unfortunately the production quantities are not broken down by model. By the VIN's and tags observed, there were 216 1967 Camaros built from 7 XCO's (with 24 cars in each) and 188 1968 Swiss Camaros from 5 XCO's. .

|

|

Swiss Camaros were unique in that they were the only production application of the 283 cu. in. V8 engine in any Camaro. This was done for tax reasons (the tax was based on engine displacement). The 230 cu. in. L6 and the 283 V8 was used in 1967 models. 1968's used the 327/210 hp engine and the SS350 model with the L48 engine was also available. Presumably the L6 engine was used too, but no 1968 L6 Swiss cars have been found so far. The transmission choice was either a Powerglide automatic or a manual 4-speed. Most cars had several options such as power windows, rear defroster, console, power disc brakes, power steering, and deluxe interior.

The Swiss plant took the most liberties of any plant with the VIN. The format was S9-YY5xxx where YY was the model year, 67 or 68. 5 was the code for Camaro (also used on U.S. window stickers). xxx was the consecutive serial number, starting at 001. The VIN on the tag below is S9-675199. The VIN was attached to the dash and also was stamped on the cowl tag. The VIN prefix in prior years used to be SS, instead of S9, but was reputedly changed due to negative connotations with Nazi Germany.

The cowl tag has four lines of information:

Line 1: Make and road homologation document.

The homologation document (called a type certificate by the Swiss) confirms

that the model is in compliance with Swiss traffic laws. This

document will be on-file with the Swiss authorities and an example is shown

to the right.

Line 2: Model and release number. The model lists the model year (as a single digit),

the model name and model series, followed by either an A for automatic or S for standard

transmission. Like the Antwerp cars, the release number is an internal tracking number.

It is the calendar year (H=66, J=67, K= 68), the XCO number, and the unit number in

the XCO.

Line 3: Motor and exterior color. The motor code is the engine suffix (sometimes the

complete engine code) stamped on the engine pad. The exterior color codes use an X and

then a 3-digit number. The meaning of the color code is undetermined.

Line 4: Chassis number (a.k.a. VIN, explained above) and interior trim.

The interior trim code also uses an unknown code format. It is in the form of XJ and

then a 3-digit number.

|

|

The 68 Camaros used the L30 (327/275hp) engine while the 69's use the LM1 350 which was replaced by the L65 350 during the model year. The cars were pretty well optioned with Rally Sport, power steering, power brakes, console, clock, and HD radiator. There was a choice between automatic and 4-speed manual transmissions. It's believed the cars with automatics also had AC and power windows. Color combinations were apparently somewhat limited - dark blue with blue standard interior and white with red standard interior were the most common ones.

The VIN was stamped on a plate attached to the dash in the normal location. The format used the U.S. VIN format but with the year indicated by a letter: H = 1968, J=1969. The plant code was C for Caracas (note that C was also used for the Southgate, CA assembly plant).

Late-69 Caracas Camaros have been found with a K (K = 1970) VIN. This would indicate that the plant was notified that the 1969 body style was going to be used for 1970. That plan changed, 1969 production was instead extended for 4 months, but the plant, for whatever reason, kept with the original plan.

The firewall tag used a U.S. trim tag. In 68, the tag was the earlier "Magic Mirror" design (also used on 68 export cars) that did not have the U.S. conformance statement on it. In 69, the tag was the normal 69 tag, but without the U.S. conformance statement stamped on it. The firewall tag was stamped with the VIN (unlike U.S. cars) and the interior and exterior color codes. Whereas the interior codes used the normal U.S. format, the exterior color codes used several different formats with six, eight, or nine digits. Some resemble DuPont paint codes, but only one observed code matches a known DuPont code.

|

|

The Peruvian Camaros apparently did not have a trim tag, only the VIN tag. The VIN used the U.S. VIN format but with the year indicated by a letter: H = 1968. The plant code was P for Peru. There were only 5 digits in the consecutive serial number after the plant code instead of the normal 6 digits. An example of a VIN would 12437HP11111.

|

|