|

|

| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

CRG Research Report - © 2018-2024, Camaro Research Group

1967-69 Camaro Driveshafts

Primary Authors - and Kurt Sonen|

Last Edit: 6-Apr-2024 Previous Edit: 19-Jan-2024 Original Release: 11-Apr-2018 |

|

|

|

|

| Year | Engine(s) | Transmission | AIM Part number |

Service Part number |

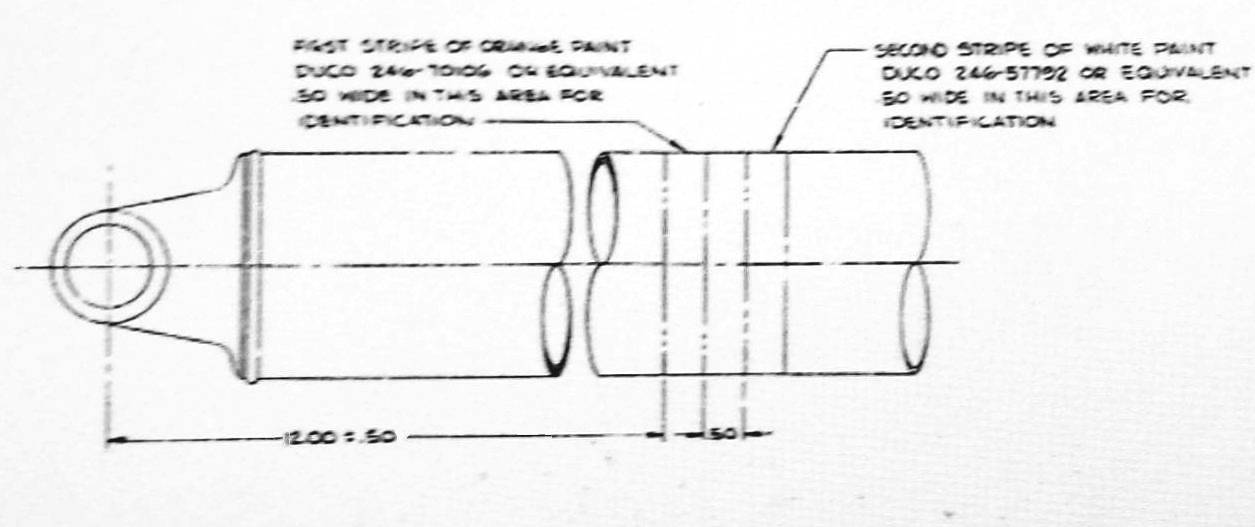

Length | Yoke diameter | Stripes |

|---|---|---|---|---|---|---|---|

| 1967 | L6 and SBC | Manual, PG | 3899009 | 3910061 | 49.96" | 1.5" | orange/white |

| 1968 | |||||||

| 1967 | BBC | Manual | n/a | 3914190 | 50.46" | 1.5" | orange/green/white |

| 1968 | |||||||

| 1967 | BBC | TH400 | n/a | 7801406 3958031 |

49.96" | 1.875" | orange/green/pink |

| 1968 | |||||||

| 1968 | SBC | TH350* | 3945544 | 3950194 | 49.56" | 1.5" | |

| 1969 | L6, SBC, 396 | Manual, PG | 3945540 | 3950194 | 49.56" | 1.5" | orange/white |

| 1969 | L6 and SBC | TH350 | 3980952 | n/a | 49.56" | 1.5" | orange/blue/pink |

| 1969 | BBC | TH400 | 3945543 | 3950196 | 49.56" | 1.875" | orange/green/purple |

| 1969 | 427 | Muncie | 49.56" | 1.5" | orange/brown/purple | ||

| * TH350 used late in the 1968 model year on 327/275hp cars as part of an internal GM test fleet. | |||||||

|

|

|

|

|

|

|

|

|

|

|

|