|

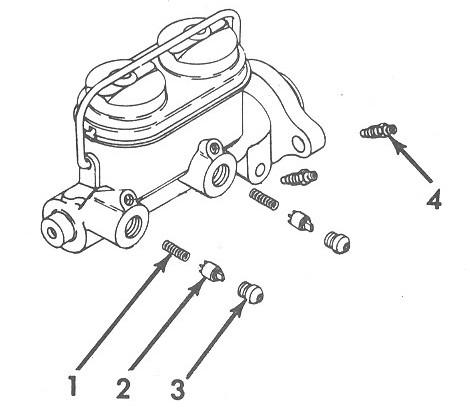

Drum brake master cylinder showing the springs(1), residual pressure valves(2), brass tube seats(3), and bleeders(4). |

| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

© 2010-2025, Camaro Research Group

Camaro Brake Valves

Author: John Hinckley

|

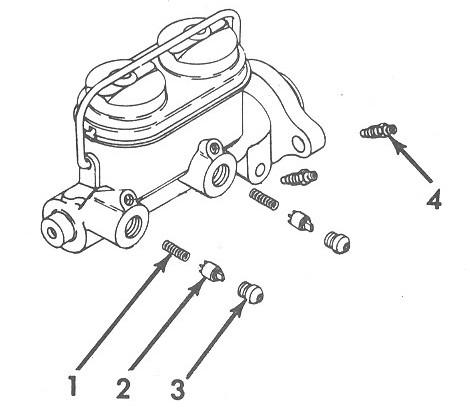

Drum brake master cylinder showing the springs(1), residual pressure valves(2), brass tube seats(3), and bleeders(4). |

|

The inlet port side of the distribution block, with the terminal connection for the differential pressure switch. |

|

|

|