Thanks for the kind interest displayed,

(Good 1:18 GMP Camaro subassembly photographs are few as when most work undertaken, I did not have a digital camera. As each Camaro is overhauled in anticipation of final finish work, I'll have more topic-specific photo images to share. Thanks... M.K.)

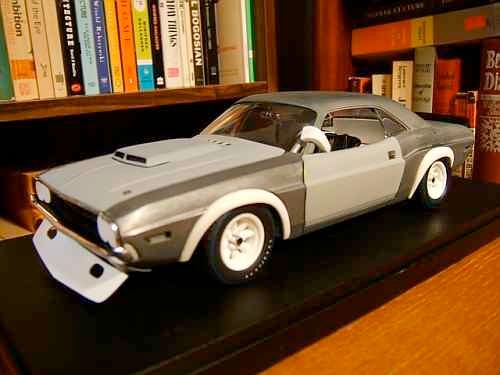

...'70 Autodynamics Sam Posey Challenger. Most conversions seen online are 1:18 ERTL-based, whereas this is a 1:18 Hwy. 61-based project. Hand-sculpted flares, massively complex to do from scratch. '68 Mustang flares to be done in the same fashion.

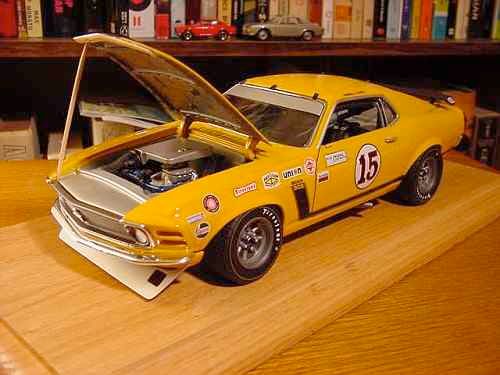

...'70 BME Parnelli Jones Boss 302. Revised from1:18 Welly '71-season Follmer release.

...'70 Penske Donohue AMC Javelin. Jimmy Flintstone resin shell combined with Jo-Han chassis - a quite complex project. Like my Racemark seat? Not sure if I should go will a late-season car, hence early kit front spoiler seen in place.

...'69 Penske Donohue underhood, needs stamped steel valve covers, firewall out, accessories and hosing/wiring to come.

...69 Shelby Racing Co. Dan Gurney Laguna Seca. Nice one-off ARE CP-200/Trans Am wheels. Wheels done in three parts but for lugs.

...'68 Shelby Racing Co. mockup. Just tires and wheels, ride height - nothing more. Will love to do the oblong headlamp block out plates.

...'67 BME Dan Gurney Cougar late-season versus early. No interior yet, but largely happy. Fender extensions hacked off with a saw, body paint touched in. Very, very butch in appearance.

...'67 Shelby Racing Co. Jerry Titus. No interior yet, also largely happy. If things come undo, well, J. Titus 'rolled his own' more than once in '67.

...'67 with 1:18 Hwy. 61 '69 Camaro-sourced 'stamped steel' fuel tank fitted versus standard GMP fitment. Not much to see, but day-to-day stuff if you will.

-

Primative point-and-shoot camera with limited manual controls restricts what detail I can capture, whereas a few further photographs of period SCCA Trans Am projects are seen above. For '67-'68 dashboards, I have a pair of 1:18 Maisto Camaro dashboards which may be mated to the mounts found on the GMP dashboards. Wish parts cars were cheap, but 1:18 Lane Camaros start at about $70, 1:18 ERTL Authentics Camaros start at about $40, whereas 1:18 Maistos are in the $30 range. A tiny network of friends who also kitbash diecasts will afford spares, and how thankful I am.

I do cast standard and modified parts in two-part resin within the space of urethane molds, largely as a means to economy. What are seen here are mainly pre-assembled and pre-finished diecast models evidencing more than a few errors that this poster has opted to correct. Some work is quite straightforward and simple, whereas other aspects quite frankly are not. Bodies are white metal, chassis largely plastic, tires rubber. Architectural sheet and rod plastic used to scratchbuild that which is missing, whereas brass and aluminum is also employed as required. Select paintwork is done upon subassemblies pulled clear of the overall work, whereas at other times items must be masked 'in situ.', this lending yet another dimension to various tasks undertaken. Hmmm - should I attempt to change this for risk of destroying a $120 model? Decisions, decisions...

Quite hard to see, but on my '69 one may discern tiny 'dymo' labels for the electrical switchgear, an aircraft 'ON/OFF/ switch with red plastic cover, as well as the dash pad covering. Many details simply can't be seen but are nevertheless there; i.e. the 'swiss-cheesed' dead pedal structure on the '69. My '69 is currently without wheels, waiting if you will for 'new cast' '69 Minilites with properly shaped spokes complete with more vibrant, almost earthy yellow paint finish applied. Will install 'stamped steel' valve covers on my '69 as well, whereas what photos are seen here are quite old. Tires pulled from '69 now fitted to dauntingly complex '70 Autodynamics Challenger - my most ambitious project by far. I move back and forth across projects, for finishing them seems a terrible bore! Again, my thanks and updates to come.

Mike K/Swede 70